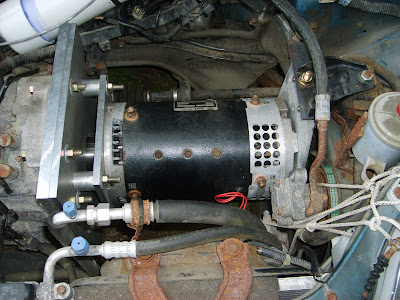

I woke up this morning to torrential rains, which was not on the forecast on Friday. So, after breakfast, I setup my tarp and went to work on installing the control tray. After about 3 hours of bolting, cable installation, checking again and again, it was done!

It wasn't without some little quirks, though. I first tested the control tray and started to smoke up my Precharger Resistor because my DC/DC was connected on the wrong side of it. I just unplugged the DC/DC until I can lengthen the wire for the positive side tomorrow.

After, I fired everything up, got in the EV and went to drive, and the Transmission wouldn't come out of park! It turns out that I had parked it funny, so I had to use the key to override the lock out, rolled down the driveway a few feet, and it was fine.

Then I went for a 1 mile jaunt around the neighborhood, and the EV had much more power now than before, with driving up to 25 MPH. I did feel like it should have had more power, but I decided to skip the step of checking the Kelly Controller settings before my little trip. After I got back, I hooked my laptop and found out that I had the wrong settings on the controller! I changed the settings and tomorrow I will go out to test them.

Now I do have a few things to work on. The vacuum has a leak in it, and my TPS sensor fell out when I installed my control tray, so I will have to reinstall that. I also have to go on a few small trips to break the brushes and batteries in again, so maybe 2 or 3 small trips this week will do that.

Once I get the little quirks out, I will make a video of the EV in action. I need about 30 minutes to fix up the little things, then I should be good for a real joy ride.

My next goal is to install the charger into the trunk. Right now it is an external setup, but I will change that and install the K&W BC-20 into the trunk so I can charge it in any weather. Then I will work on the Power Steering and the Air Conditioning, but that's later on.