The first thing I did was design a motor coupling and plates that mimicked the old ICE. I kept the torque converter and flywheel setup, and since it mimics the original engine, the adapter plates and motor coupling can be used with the automatic or a manual transmission. I used the transmission's Flex Plate to design the motor coupler, which is a taper locking coupling. The aluminum plates were created using a second transmission I bought off Craiglist because at the time the car was still driving and I wanted to have as little down time as possible, so I bought the second transmission (which was skipping gears) as a EV sacrifice so I could use it as a template for the coupling and for the bolt hole pattern on the plates.

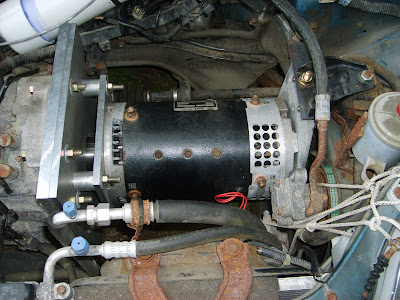

Next, I left the Automatic transmission installed with the existing radiator/transmission cooler. I also left the PCM and ECU installed as they are needed to operate the transmission and the dash board. I also used the old engine mount to hold up the rear side of the 9" ADC FB1-4001A series wound motor. The motor has a rear shaft that will connect to the Power Steering pump and A/C compressor.

Next, I left the Automatic transmission installed with the existing radiator/transmission cooler. I also left the PCM and ECU installed as they are needed to operate the transmission and the dash board. I also used the old engine mount to hold up the rear side of the 9" ADC FB1-4001A series wound motor. The motor has a rear shaft that will connect to the Power Steering pump and A/C compressor. After all the mechanical is done, comes "fooling" the PCM. I Do not idle the motor at all. It does take about 6 seconds to build up pressure for the clutches to operate, but that only happens when the EV is first started before a trip. During driving the pressure stays up while at stop lights and such, and getting going again is no slower than with using a manual with a clutch.

After all the mechanical is done, comes "fooling" the PCM. I Do not idle the motor at all. It does take about 6 seconds to build up pressure for the clutches to operate, but that only happens when the EV is first started before a trip. During driving the pressure stays up while at stop lights and such, and getting going again is no slower than with using a manual with a clutch.Now comes the big question: How did I change the shift points on the transmission? Did I reprogram the PCM? Modify the transmission soleniods? I did nothing of the sort! The key to using to changing the shift points: replace the TPS with a 5 k potentiometer!

In and ICE he TPS tells the transmission when to shift, depending on how hard the pedal is pressed, when accelerating or cruising or coasting. By replacing the TPS with a 5K potentiometer I now can manually tell the PCM when to shift. The higher I set it, the longer it stays in each gear. After 1,000 miles of driving like this, I have had no problems and I have found a few settings that work well depending on which terrain I drive on. Higher RPMS mean better efficiency while lower RPMS allow for better acceleration.

In and ICE he TPS tells the transmission when to shift, depending on how hard the pedal is pressed, when accelerating or cruising or coasting. By replacing the TPS with a 5K potentiometer I now can manually tell the PCM when to shift. The higher I set it, the longer it stays in each gear. After 1,000 miles of driving like this, I have had no problems and I have found a few settings that work well depending on which terrain I drive on. Higher RPMS mean better efficiency while lower RPMS allow for better acceleration.I usually leave it at about 1/4 turn, however it needs to be set to 0 every time I start up the EV because if the TPS (5k pot) is higher than 0, the transmission thinks you are stepping on the gas and will lock the Shifter into place so you cant move it from Park. Annoying, but effective safety measure. And I will not be bypassing that protocol, but if I do the transmission can easily be shifted into Neutral with the EV off, and that is a safety issue that is checked during the yearly Inspection.